Previous: CK0620A2 小型精密排刀式数控车床

Next: B20 双主轴数控走心机

|

机床型号 |

BY32S |

||||

|

机床参数 |

|||||

|

电源 |

电源额定电压 |

三相交流380V |

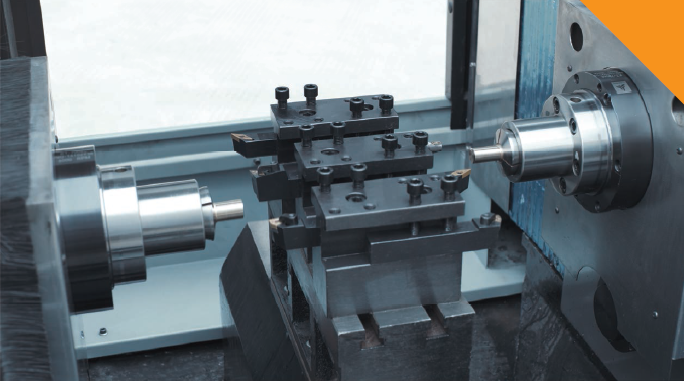

排刀系统 |

T型槽排刀式 |

|

|

电源额定频率 |

50HZ |

||||

|

总输入功率 |

10.8kw |

||||

|

数控系统 |

BYSK |

YZ150 |

|||

|

最小设定单位 |

0.001mm |

||||

|

X轴脉冲当量 |

0.0005mm |

冷却系统 |

切削油用电机功率 |

0.12kw |

|

|

冷却箱容量 |

150L |

||||

|

Z轴脉冲当量 |

0.001mm |

润滑系统 |

马达功率 |

25w |

|

|

最大编程尺寸 |

±9999.999 |

容量 |

2L |

||

|

切削速度 |

1--4000mm/min |

||||

|

X轴快速进给速度 |

20000mm/min |

液压系统 |

液压马达功率 |

0.75kw |

|

|

油压压力 |

3.0Mpa |

||||

|

Z轴快速进给速度 |

20000mm/min |

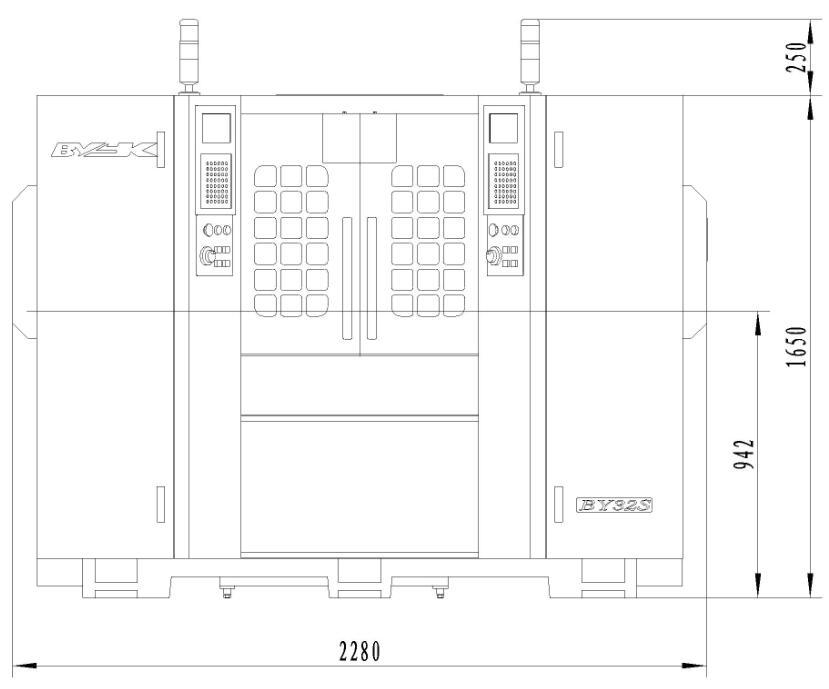

机床尺寸 |

长*宽*高 |

2280*1970*1900 |

|

|

主轴 |

最大棒料直径 |

Φ32mm |

机床重量 |

||

|

主轴通孔直径 |

Φ33mm |

可选配置 |

|||

|

最大旋转直径 |

Φ130mm |

||||

|

主轴中心离地面高度 |

942mm |

||||

|

主轴转速 |

0-4000r/min |

||||

|

主轴马达功率 |

2.2kw/3.7kw |

||||

|

行程 |

X轴行程 |

700mm(直径量) |

|||

|

Z轴行程 |

200mm |

||||

|

X轴伺服马达功率 |

1.3kw |

||||

|

Z轴伺服马达功率 |

1.3kw |

||||

|

滑轨形式 |

直线导轨 |

||||

BY32S双主轴移动式数控排刀车床参数:

|

机床配置 |

|||

|

名称 |

型号/规格 |

厂家 |

|

|

系统 |

BYSK180系统 |

自制 |

|

|

主轴 |

32主轴单元 |

自制 |

|

|

X轴电机 |

1.3kw绝对值伺服电机 |

汇川+总线 |

|

|

Z轴电机 |

1.3kw绝对值伺服电机 |

汇川+总线 |

|

|

X轴丝杆 |

500*3210 |

跃尔 |

|

|

Z轴丝杆 |

690*3210 |

跃尔 |

|

|

X轴导轨 |

HGW30 |

中国台湾品牌 |

|

|

Z轴导轨 |

HGH30 |

中国台湾品牌 |

|

| 主轴电机 | 4kw伺服主轴电机 | 阿尔法 | |

|

|||

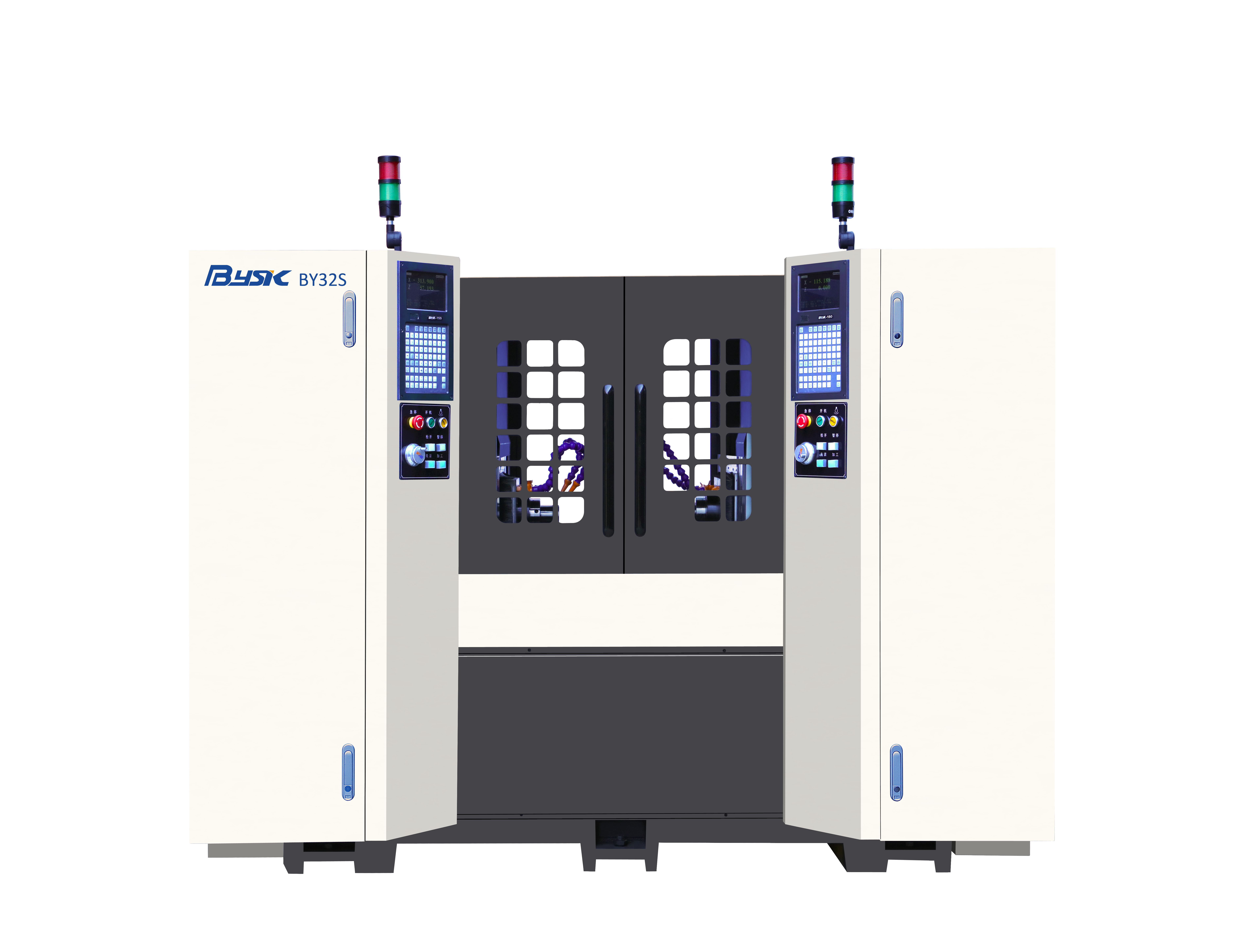

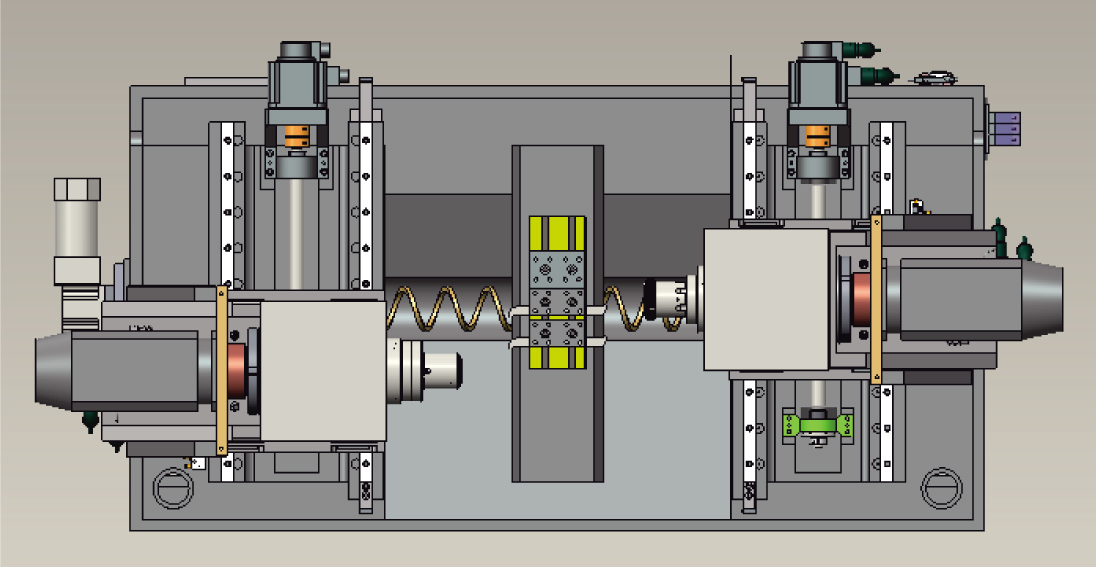

The BY32S dual-spindle mobile CNC gang tool lathe features a structure where two main spindles are arranged in parallel and opposite to each other, with the gang tool post fixed in the middle of the machine. Both spindles can independently execute programs for X-axis and Z-axis movement, enabling automatic exchange of workpieces between the main spindle and the sub-spindle. This resolves the machining problem of performing two operations on the clamping end of the workpiece in a single setup.

The machine offers several advantages, including fast tool change, high positioning accuracy, high production efficiency, labor savings, and a high cost-performance ratio. Additionally, various forms of automated loading and unloading mechanisms, such as vibrating plates, can be integrated into the machine to achieve unmanned automatic processing. The machine combines two functions into one, saving on floor space.

The BY32S dual-spindle mobile CNC gang tool lathe features a unique design with dual spindles and dual systems

1. Combining two independent lathes into one, and utilizing two sets of CNC systems, it can operate independently or work together to complete the other half of the machining process.

2. This is equivalent to operating two lathes, but it offers the added benefits of saving floor space, reducing the number of operators, and minimizing material handling and setup time.

3. By integrating various automated loading and unloading mechanisms, such as vibrating plates, it achieves unmanned automatic processing.

4. A servomotor with an absolute encoder prevents errors caused by power outages.

Main business:CNC machine tools, automated production lines, industrial robots